Author Archives: Shrimpl

Aquaculture as an industry has a negative image, most of which has been constructed from an idea of what the industry is based on the production practices used during the 1980s and 90s. This is especially true for shrimp aquaculture, which has been pointed out several times as the most damaging of all aquaculture productions due to the mangrove depletion, the abandonment of farm sites, the high use of fishmeal and fish oil, the emission of highly pollutant effluents, the overexploitation of natural stocks, and the eutrophication of soils. Although the bases for this asseveration were valid in their time, right now, thanks to the new management technologies, this panorama has shifted drastically.

All different shrimp aquaculture stakeholders have taken the industry’s sustainability very seriously. Farmers have understood that they need to improve their management practices to keep up production and increase profits in the long run. Also, consumers have been ever more demanding of sustainable practices, asking for smaller carbon footprints, less water use, better treatment for their employees, increased traceability, and overall better practices; and they are willing to pay more for that. Furthermore, there has been a good response from the technology developers and researchers. In general, concerns from the academy, NGOs, and most involved stakeholders are being tackled by the industry players looking to improve management practices and reduce their negative impacts on the environment.

But let’s keep in mind that shrimp farming is a business, so the solutions proposed to improve the environmental footprint of production need to be profitable to introduce so that the industry keeps going (emphasis on the word sustainability). Let’s remember that this activity also has positive impacts, such as its effect on the accessibility to shrimp (significantly reducing its price and increasing its presence in world markets), its impact on food security (although not cheap, the industry produced more than 4 million tons of product in 2021), and the significant number of direct and indirect jobs it creates especially in coastal communities. Furthermore, it reduces the pressure in shrimp fisheries, making possible a more sustainable management, reducing the risk of violating fishing bans, and reducing the potential of illegal fishing.

With all that in mind, management techniques have been improving over the last decades leading to new production methods that we will review over the following weeks. In order to be considered sustainable, these techniques need to account for the following points:

1.- They need to reduce the activity’s environmental impact significantly. Some things to keep in mind and to aim for are the reduction of feed intake, the minimization of water and energy use, the elimination or reduction of polluting effluents, the minimization of production area, the maximization of the production site’s lifetime, the distance to the final consumer market, and the use of highly available materials and low ecological footprint inputs.

2.- New techniques must account for the social impacts of the activity, being the most significant food security, well-being (for direct workers and impacted communities), and animal welfare. Other management components need to be considered to become a more sustainable business, but they don’t depend on the production technique used, for example, gender and racial equality.

3.- The methods applied need to be at least as profitable as a classic open system management method. All the purchased inputs, technologies, gadgets, and consultancies need to be included in the cost of production, and in the end, new systems need to be at least as good; otherwise, their implementation will be extremely challenging among farmers. That means that although there might be a new technology that significantly reduces the impacts of the activity, if its implementation does not come hand in hand with an increase in revenue, a reduction in production costs, or a price increase, then that technology is doomed at an industrial level, which is the area that has the most significant impact on the ecosystem and society.

As you can see, technologies need to cover all spheres of sustainability (the environment, society, and economics). There is an extra transversal tool to sustainable management that can help boost sustainable aquaculture, and that is governance. In very simple terms, governance is the mechanism through which a community sets rules; in the case of private business, governance is also known as corporate governance. Although these components are very important for sustainable development and achieving the UN sustainable development goals (SDGs), and that’s why they deserve mention in this article, we will not deepen in it on this occasion; we’ll just emphasize that it needs to be taken into consideration when implementing or changing the production technologies or management systems.

Over the following weeks, we will discuss the most established technologies that might be considered sustainable in shrimp aquaculture. First, we will talk about the Biofloc Technology System (BTS), which consists in promoting the growth of beneficial bacteria and other microorganisms in the pond to stabilize different water components.

Secondly, we’ll cover recirculating aquaculture systems (RAS), which mainly consist of reusing culture water, minimizing hydric footprint and maximizing productivity per unit of area.

On the third delivery, we will cover the technology that combines BTS and RAS, also known as bio-RAS, which seeks to combine the benefits of the two previously mentioned technologies.

In our fourth installment, we will talk about Aquamimicry technology, which consists of mimicking the natural environment in the best way possible, reducing risks and harms, and boosting the benefits of the shrimp’s natural habitat.

Finally, we will cover what most researchers consider the future of sustainable aquaculture, Integrated Multitrophic Aquaculture, which consists of the production of several different species that are capable of using the residues of each other to increase biomass production and minimize environmental impacts.

Even though some of these technologies are not as new and have a very established position in industrial aquaculture, they are worth a mention, and sometimes their basics are not very well understood, which might translate into poor management, resulting in negative effects, but not due to the technology itself but as a result of the reduced understanding of the basic concepts that drive the technology.

So, if you wonder why your BTS is not working or if you should invest in RAS technology, we invite you to stay tuned to Shrimpstar throughout our upcoming series.

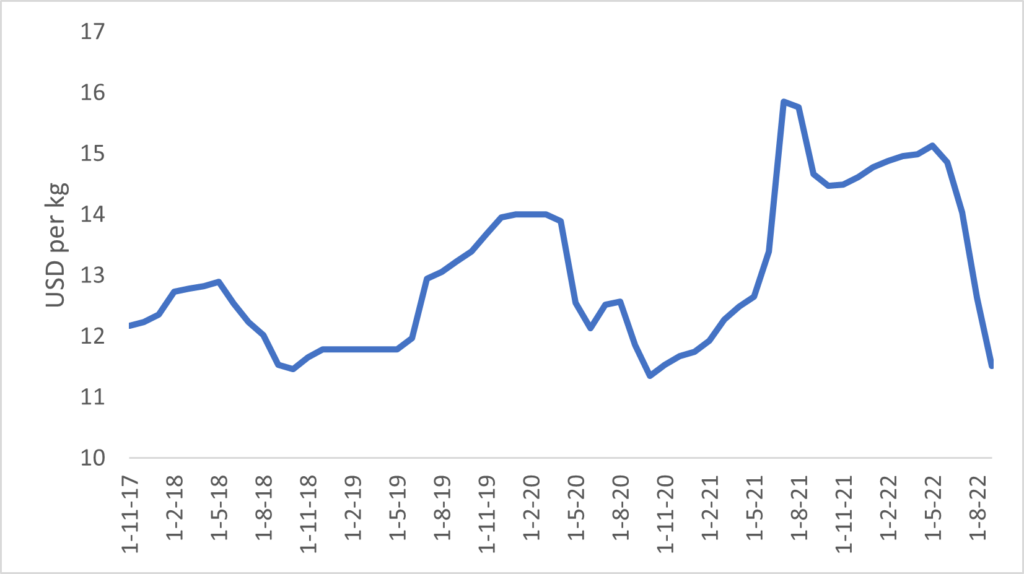

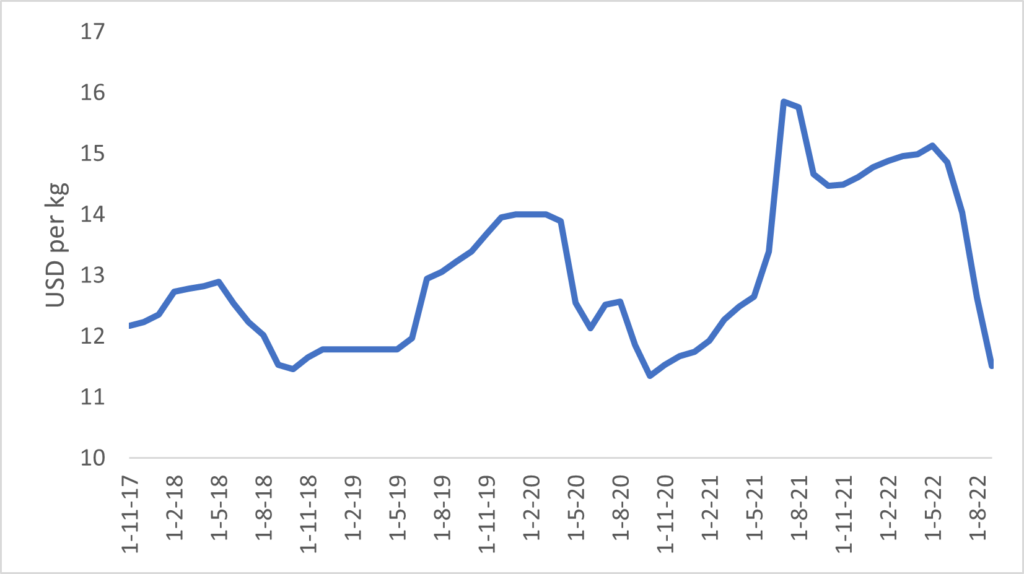

Most shrimp farmers worldwide have suffered from low prices this year. Shrimp prices, like all commodities, are determined by supply and demand. Basically, when supply is low and demand is high, prices tend to go up, and the opposite; when demand is low and supply is high, prices tend to go down.

During the pandemic, shrimp demand was expected to be reduced due to the closure of restaurants and the reduction of tourism worldwide. Furthermore, the uncertainty derived from the COVID-19 crisis led to an expected reduction in imports from the main markets. As a response to this (as well as other significant factors, such as impacts on the logistics chain), global marine shrimp production slowed down, being 15% lower in 2020 compared to 2019.

As opposed to other agricultural goods, shrimp is considered somewhat of a luxury or a non-essential part of the diet. Unfortunately for shrimp farmers, high inflation severely impacted demand. Since all goods increased their price, consumers tended to ditch those products considered luxury first, which made the demand grow slower than supply, plumbing the average prices worldwide.

The previous lines are just a part of the reason why shrimp prices went down; there are other macro and micro factors that drove the price of this crustacean, but the intention of this article is not to unveil all the reasons that made prices drop. What is certain is that, in a minor or major way, shrimp prices worldwide dropped. Over the following lines, we present some ideas any farmer can implement to improve their profitability.

1.- Look for new markets

The first thing that comes to mind when considering low-selling prices is to look for higher-value markets, mainly existing in higher-income countries such as the US, the EU, Japan, and Australia. Although the solution seems easy, it isn’t as simple as it looks. One has to:

a) Have a potential buyer for the product in the stipulated market willing to pay more for our product. Remember that shrimp is a highly traded commodity, meaning there will be several other producers looking into these markets, so; why should they buy your product instead of anyone else’s? Especially if you are looking for a price premium. To look for these premiums, you must provide a product that differentiates from the rest. We will come back to this later, but differentiation essentially includes any trait that separates your shrimp from the rest and which is appreciated by the sought market.

b) Fulfill all of the client’s requirements for the product. In these markets, there might be several requirements to fulfill if you want to be able to ship and sell in that country. There is no one specific requirement to enter all these markets, each country or group of countries has its own importing standards, but the most common ones are the Best Practice certifications (depending on the market, they accept one or another, but always from a trustworthy entity such as the Aquaculture Stewardship Council or the Global Seafood Alliance).

c) Consider all the incurred costs before compromising your production. Differentiating your product, complying with the market requirements, and shipping your product have associated costs, which need to be included in your production costs to determine if the price premium gained will improve the farm’s profitability or only increase your workload without gaining anything from it.

For example, say your production costs amount to 4.5 USD per kg, and your local selling price is 5 USD per kg. You get a buyer from the US who is willing to pay 7 USD per kg, but freight costs amount to 2 USD per kg. You will end up with a total cost of 6.5 USD per kg, making your marginal profits equal to those obtained in the local market, but with increased workload and risk associated with a larger freight.

2.- Differentiate your product

As stated in the previous point, one way to increase the value of your production is to differentiate from the rest of the shrimp producers, making the buyers seek your product instead and hence obtain a price premium. Again, this is a game of supply and demand. Looking for appreciated traits in the market and where customers are willing to spend more would be best. These traits are not equal for every market; for example, the European market, along with some US states, are heavily invested in low- environmental footprint products and willing to pay more for these products.

To have a better environmental performance, the producer can look into reducing its carbon footprint, either by reducing energy consumption or investing in clean energy generation; they can also repopulate carbon sinks (like mangrove forests) and care for them. Apart from carbon footprint, producers can look into reducing their hydric footprint by minimizing water exchange and reducing the emission of polluting effluents.

Reducing the environmental footprint is important to the previously mentioned markets, so once the producer has achieved a “cleaner” shrimp production, it needs to be labeled adequately so that the product is effectively differentiated from other shrimp products.

Minimizing the environmental footprint can be useful, but it isn’t the only appreciable trait. Some markets have an intense appreciation for the shape, color, and consistency of the shrimp; that is the case of the Japanese market, which looks for freezing methods that are capable of maintaining the consistency and flavor of the product.

Also, not all differentiation needs to be targeted to foreign markets. There might be niche markets within your current region that will pay higher prices for specific products. You can differentiate your shrimp by its quality, color, or production methods; maybe you can advertise your policies regarding fair labor and governance; or a simple classic, freshness. If you look into nearby markets, you can compete with imported frozen shrimp by providing same-day caught shrimp. There are several ways of differentiating your product, and there is no single solution; it depends on your market, production methods, and creativity.

3.- Optimize your unit production costs

Although it is number three on this list, this should be the first thing any producer tackles when prices are low. Optimizing your production costs does not necessarily entail reducing investment or minimizing your total costs; it usually is the other way around; investing in better methods may result in lower average unit costs (AUC).

To optimize your AUC (that is, how much does each unit, i.e., kg of shrimp, cost), you first need to gather, organize and visualize your production data.

Once you have your data visualization, you can start analyzing where are your higher costs and how you can optimize them. Are you giving an optimum amount of feed? What is your FCR, and is it similar to other producers’? Are you using too much energy? Can you optimize the use of additives? Are you seeding at an optimum season, size, and density? All these will have an impact on your final AUC. Remember that the lower your AUC, the smaller the impact of low prices; furthermore, you can only benefit from price increases.

There are several ways of optimizing your unit production costs, all of which require a certain amount of expertise. Today, data management and analysis software is available for shrimp producers to help them organize, visualize and analyze their data. Suppose the software tools are not enough for your needs. In that case, you can complement that by hiring a data analysis team or a consultant to manipulate, analyze and extract the most value out of your data to obtain better insights and optimize your farm operations. This is standard practice in most agriculture operations and other animal productions like pigs and chickens.

4.- Invest in storage

Most producers are exposed to the impacts of low prices due to the impossibility of storing shrimp. When prices are low, producers have two options: either they keep them in the ponds, where costs only increase (due to feeding mainly) while productivity decreases (as a result of higher mortality), or they harvest; but once harvested, shrimp needs to be either consumed or transformed for storage (dried, frozen or transformed to increase the shelf-life of the product). If the farmer cannot transform and store their product, they can only sell at a price given to them by the buyer, putting the farmers in a price-taker situation.

Furthermore, if the farmer has not looked into other markets and has only one potential buyer, they are at the mercy of their prices since there is nowhere else to sell. This could lead to selling the product under the market value, and in some cases, under their AUC, making the farmer lose money and, in extreme cases, to the closure of the farm.

The farmer can invest in a transformation and/or storage system to solve this problem and gain some negotiating power. This way, he can decide not to sell their product under specific dictated prices and keep them in storage, waiting for prices to go back up. To fully understand this, let’s go back to the supply and demand aspect of the article once more.

If the price of shrimp is too low, that means that supply is higher than demand at that particular moment (maybe a lot of farmers are harvesting, flooding the market with the product); if you cannot store your product, you have to sell at that same price. On the other hand, if you can store your shrimp, you can decide to wait until that excess supply is gone (once all the previous batch of shrimp is consumed and there are no other farms harvesting). At that moment, supply will be lower than demand, making prices go up again, and you can opt to sell your shrimp at a higher price.

Although the theory is quite strong and has been proven true, you must asses all your costs before investing in storage and evaluate if the excess price justifies the investment. One good way to diversify risk and make storage affordable is to look into co-investing with other shrimp producers in the area, increasing the negotiation power of the group with storage capacity and higher production volumes. It is essential to include the cost of freezing and keeping your product stored in your average unit production costs so that the higher price obtained actually results in higher profits.

Even though we presented the different options in a list, they are not exclusive. The best way to face low prices is to tackle all the points listed simultaneously as far as possible. But even if we can only tackle one, that might increase our chances of having a profitable business.

Finally, although we believe the four points listed are the most significant ways of facing low prices, there are other alternatives, like better financing, cooperative-like governance structures for production and sales, or exploiting new selling points, for example, through a digital marketplace.

Most shrimp farmers worldwide have suffered from low prices this year. Shrimp prices, like all commodities, are determined by supply and demand. Basically, when supply is low and demand is high, prices tend to go up, and the opposite; when demand is low and supply is high, prices tend to go down.

During the pandemic, shrimp demand was expected to be reduced due to the closure of restaurants and the reduction of tourism worldwide. Furthermore, the uncertainty derived from the COVID-19 crisis led to an expected reduction in imports from the main markets. As a response to this (as well as other significant factors, such as impacts on the logistics chain), global marine shrimp production slowed down, being 15% lower in 2020 compared to 2019.

As opposed to other agricultural goods, shrimp is considered somewhat of a luxury or a non-essential part of the diet. Unfortunately for shrimp farmers, high inflation severely impacted demand. Since all goods increased their price, consumers tended to ditch those products considered luxury first, which made the demand grow slower than supply, plumbing the average prices worldwide.

The previous lines are just a part of the reason why shrimp prices went down; there are other macro and micro factors that drove the price of this crustacean, but the intention of this article is not to unveil all the reasons that made prices drop. What is certain is that, in a minor or major way, shrimp prices worldwide dropped. Over the following lines, we present some ideas any farmer can implement to improve their profitability.

1.- Look for new markets

The first thing that comes to mind when considering low-selling prices is to look for higher-value markets, mainly existing in higher-income countries such as the US, the EU, Japan, and Australia. Although the solution seems easy, it isn’t as simple as it looks. One has to:

a) Have a potential buyer for the product in the stipulated market willing to pay more for our product. Remember that shrimp is a highly traded commodity, meaning there will be several other producers looking into these markets, so; why should they buy your product instead of anyone else’s? Especially if you are looking for a price premium. To look for these premiums, you must provide a product that differentiates from the rest. We will come back to this later, but differentiation essentially includes any trait that separates your shrimp from the rest and which is appreciated by the sought market.

b) Fulfill all of the client’s requirements for the product. In these markets, there might be several requirements to fulfill if you want to be able to ship and sell in that country. There is no one specific requirement to enter all these markets, each country or group of countries has its own importing standards, but the most common ones are the Best Practice certifications (depending on the market, they accept one or another, but always from a trustworthy entity such as the Aquaculture Stewardship Council or the Global Seafood Alliance).

c) Consider all the incurred costs before compromising your production. Differentiating your product, complying with the market requirements, and shipping your product have associated costs, which need to be included in your production costs to determine if the price premium gained will improve the farm’s profitability or only increase your workload without gaining anything from it.

For example, say your production costs amount to 4.5 USD per kg, and your local selling price is 5 USD per kg. You get a buyer from the US who is willing to pay 7 USD per kg, but freight costs amount to 2 USD per kg. You will end up with a total cost of 6.5 USD per kg, making your marginal profits equal to those obtained in the local market, but with increased workload and risk associated with a larger freight.

2.- Differentiate your product

As stated in the previous point, one way to increase the value of your production is to differentiate from the rest of the shrimp producers, making the buyers seek your product instead and hence obtain a price premium. Again, this is a game of supply and demand. Looking for appreciated traits in the market and where customers are willing to spend more would be best. These traits are not equal for every market; for example, the European market, along with some US states, are heavily invested in low- environmental footprint products and willing to pay more for these products.

To have a better environmental performance, the producer can look into reducing its carbon footprint, either by reducing energy consumption or investing in clean energy generation; they can also repopulate carbon sinks (like mangrove forests) and care for them. Apart from carbon footprint, producers can look into reducing their hydric footprint by minimizing water exchange and reducing the emission of polluting effluents.

Reducing the environmental footprint is important to the previously mentioned markets, so once the producer has achieved a “cleaner” shrimp production, it needs to be labeled adequately so that the product is effectively differentiated from other shrimp products.

Minimizing the environmental footprint can be useful, but it isn’t the only appreciable trait. Some markets have an intense appreciation for the shape, color, and consistency of the shrimp; that is the case of the Japanese market, which looks for freezing methods that are capable of maintaining the consistency and flavor of the product.

Also, not all differentiation needs to be targeted to foreign markets. There might be niche markets within your current region that will pay higher prices for specific products. You can differentiate your shrimp by its quality, color, or production methods; maybe you can advertise your policies regarding fair labor and governance; or a simple classic, freshness. If you look into nearby markets, you can compete with imported frozen shrimp by providing same-day caught shrimp. There are several ways of differentiating your product, and there is no single solution; it depends on your market, production methods, and creativity.

3.- Optimize your unit production costs

Although it is number three on this list, this should be the first thing any producer tackles when prices are low. Optimizing your production costs does not necessarily entail reducing investment or minimizing your total costs; it usually is the other way around; investing in better methods may result in lower average unit costs (AUC).

To optimize your AUC (that is, how much does each unit, i.e., kg of shrimp, cost), you first need to gather, organize and visualize your production data.

Once you have your data visualization, you can start analyzing where are your higher costs and how you can optimize them. Are you giving an optimum amount of feed? What is your FCR, and is it similar to other producers’? Are you using too much energy? Can you optimize the use of additives? Are you seeding at an optimum season, size, and density? All these will have an impact on your final AUC. Remember that the lower your AUC, the smaller the impact of low prices; furthermore, you can only benefit from price increases.

There are several ways of optimizing your unit production costs, all of which require a certain amount of expertise. Today, data management and analysis software is available for shrimp producers to help them organize, visualize and analyze their data. Suppose the software tools are not enough for your needs. In that case, you can complement that by hiring a data analysis team or a consultant to manipulate, analyze and extract the most value out of your data to obtain better insights and optimize your farm operations. This is standard practice in most agriculture operations and other animal productions like pigs and chickens.

4.- Invest in storage

Most producers are exposed to the impacts of low prices due to the impossibility of storing shrimp. When prices are low, producers have two options: either they keep them in the ponds, where costs only increase (due to feeding mainly) while productivity decreases (as a result of higher mortality), or they harvest; but once harvested, shrimp needs to be either consumed or transformed for storage (dried, frozen or transformed to increase the shelf-life of the product). If the farmer cannot transform and store their product, they can only sell at a price given to them by the buyer, putting the farmers in a price-taker situation.

Furthermore, if the farmer has not looked into other markets and has only one potential buyer, they are at the mercy of their prices since there is nowhere else to sell. This could lead to selling the product under the market value, and in some cases, under their AUC, making the farmer lose money and, in extreme cases, to the closure of the farm.

The farmer can invest in a transformation and/or storage system to solve this problem and gain some negotiating power. This way, he can decide not to sell their product under specific dictated prices and keep them in storage, waiting for prices to go back up. To fully understand this, let’s go back to the supply and demand aspect of the article once more.

If the price of shrimp is too low, that means that supply is higher than demand at that particular moment (maybe a lot of farmers are harvesting, flooding the market with the product); if you cannot store your product, you have to sell at that same price. On the other hand, if you can store your shrimp, you can decide to wait until that excess supply is gone (once all the previous batch of shrimp is consumed and there are no other farms harvesting). At that moment, supply will be lower than demand, making prices go up again, and you can opt to sell your shrimp at a higher price.

Although the theory is quite strong and has been proven true, you must asses all your costs before investing in storage and evaluate if the excess price justifies the investment. One good way to diversify risk and make storage affordable is to look into co-investing with other shrimp producers in the area, increasing the negotiation power of the group with storage capacity and higher production volumes. It is essential to include the cost of freezing and keeping your product stored in your average unit production costs so that the higher price obtained actually results in higher profits.

Even though we presented the different options in a list, they are not exclusive. The best way to face low prices is to tackle all the points listed simultaneously as far as possible. But even if we can only tackle one, that might increase our chances of having a profitable business.

Finally, although we believe the four points listed are the most significant ways of facing low prices, there are other alternatives, like better financing, cooperative-like governance structures for production and sales, or exploiting new selling points, for example, through a digital marketplace.